What is PCBA ?

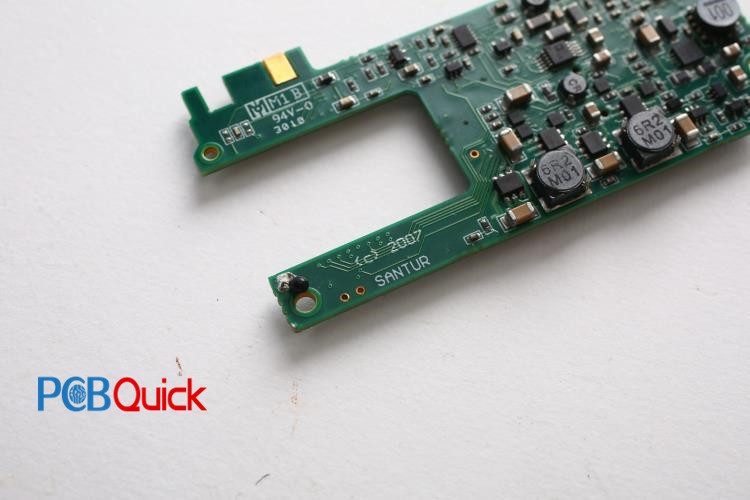

PCBA (Printed Circuit Board Assembly) is the pcb board which obtains after all printing solder paste on the PCB and then mounting various components like resistors, ICs (Integrated Circuits), capacitors and any other components like transformers depending on the application and desired characteristics of the board.PCBA usually undergoes reflow furnace heating so as to establish a mechanical connection between the PCB and the components.

SMT & DIP:

SMT and DIP both are the way to integrate parts on the PCB circuit boards. The main difference is that the SMT does not need to drill holes in the PCB, the DIP needs to insert the parts' pin feet into the holes that have been drilled.

SMT (surface mounted technology) mainly uses mounting machine,assembling some small parts of the mount to the PCB board.The production process as following: PCB board, solder paste printing, Mount mount machine, a reflow oven and made test. With the development of science and technology, SMT can also mount some large size parts, such as the main board can mount some larger body parts.

SMT integration of location and the size of parts is very sensitive, in addition the quality of solder paste and printing also play a key role.

Dip is the "plug-in components", which is inserted into the parts in the PCB version, because parts of large size and is not applicable in the form of integrated parts to mount the production process or production not taking use of SMT technology. At present, the industry has two kinds of robot and artificial plug-in plug-in method, its main production process: paste (to prevent gum tin plating should not place), plug-in, test, wave crest welding, brush Version (left in the furnace in the process of removing stains) and made test.

Maybe it’s helpful to you:

Web link: