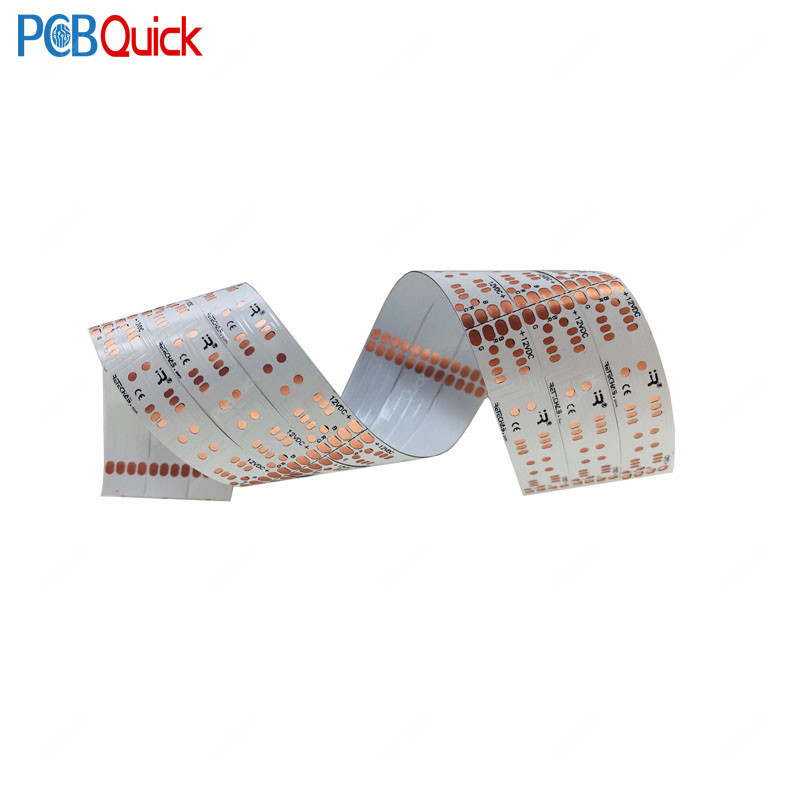

PCBQuick requirements for the production of LED strips:

(1) FPC adopts calendaring copper with environmental certification, UL certification, CE certification and ROHS certification.

(2) The thermal conductivity of silica gel is good.

(3) The color splitter ensures the same color.

(4) Adopt SMT patch technology and machine reflow soldering to ensure the appearance of the lamp.

(5) The use of high-grade chip aging time control in 12 hours, brightness to meet the requirements.

PCBQuick provides customized services for customers of LED strip, design, production, quality inspection, packaging and shipment of unconventional LED strip.

(1) Line design: when the wiring distance is above 0.5mm, the space outside the line is copper, and the copper thickness is 1-1.5OZ.

(2) Ensure the quality of FPC, choose calendaring copper material, no bending and high temperature will not occur.

Select LED chip strictly according to customer’s requirement and cost, choose import chip in the case of high quality, use Taiwan chip, the China brand chip can reduce more cost and can be customized.

(3) LED lamp belt adopts SMT patch technology to ensure smooth solder joints, static protection in production and prevent chip from being broken.

(4) To ensure that the LED lamp is clean on the surface.

(5) Use antistatic reel packing.