What does Rigid-flex PCB Mean ?

What does Rigid-flex PCB Mean ?

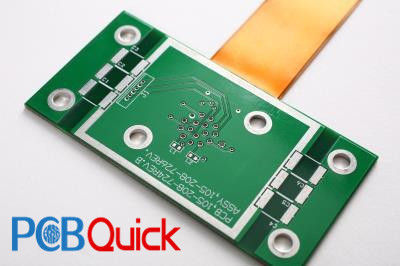

Rigid-flex pcb boards are composed of a combination the best of both rigid boards and flexible circuits that are permanently connected to one printed circuit boards. Rigid-flex pcb boards provide higher component density and better quality control. Most rigid-flex pcb boards consist of multiple layers of flexible circuit inner layers attached to one or more rigid boards.As for rigid layer pcb board is placed on externally, internally or both,which depends upon the design of the application.

Rigid-flex PCB Applications:

Rigid-flex pcb is more expensive than alternative flex pcb,so ideal applications require maximum of three dimensional space.Rigid-flex pcb circuit board is usually used in medical,aerospace,military,connector,and display equipment and so on.

The Advantages of Rigid-flex PCB:

The application of Rigid-Flex pcb printed circuit boards offers optimum solutions for difficult, limited space conditions. The first advantages is that this technology offers the possibility of a secure connection of device components with the assurance of polarity and contact stability, as well as reducing in plug and connector components.

Furthermore,the advantages of Rigid-Flex pcb is dynamic and mechanical stability, leading to installing simplified, saving space and maintaining of uniform electrical characteristics.

Last but not least,rigid flex pcb boards designs are more challenging than the design of a typical rigid board environment, so these boards are designed in a 3D space, which also offers greater spatial efficiency. By being able to design in three dimensions rigid flex

Maybe it’s helpful to you:

Web link