How to Design Multilayer pcb

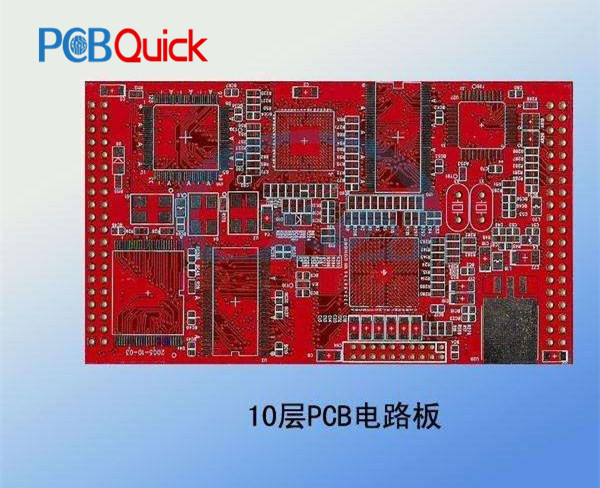

Multilayer PCB can be defined as a printed circuit board that has more than two copper layers, such as 4L, 6L, 8L, 10L, 12L, etc. Comparing to double-sided with two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material, which are buried in the center of the material.

With the improvement and development of technology, people can put more and more copper layers on the same board. Currently, we,Shenzhen Kingfung PCB Factory, can produce 2L-30L FR4 MultiLayer PCB.

For example, there is a kind of multilayer PCB--12layer 2oz PCB Board layer stack up:

-----------------1.5oz L1

1080*2116 6.5mil

----------------- L2

| 0.18mm 2oz |

----------------- L3

1080*2116 6.5mil

----------------- L4

| 0.18mm 2oz |

----------------- L5

1080*2116 6.5mil

----------------- L6

| 0.18mm 2oz |

----------------- L7

1080*2116 6.5mil

----------------- L8

| 0.18mm 2oz |

----------------- L9

1080*2116 6.5mil

----------------- L10

| 0.18mm 2oz |

----------------- L11

1080*2116 6.5mil

-----------------1.5oz L12

Lamination thickness:1.9+/-0.15M

Compared to single or double-sided PCBs, multilayer pcb has many benefits, such as :

1.Having higher assembly density

2.Having Smaller size (considerable savings on space)

3.Increasing flexibility

4.More Easier incorporation controlled impedance features.

5.Reducing the need for interconnection wiring harnesses

6.Reducing overall weight

Maybe it’s helpful to you:

Web link