PCB Measling Crazing

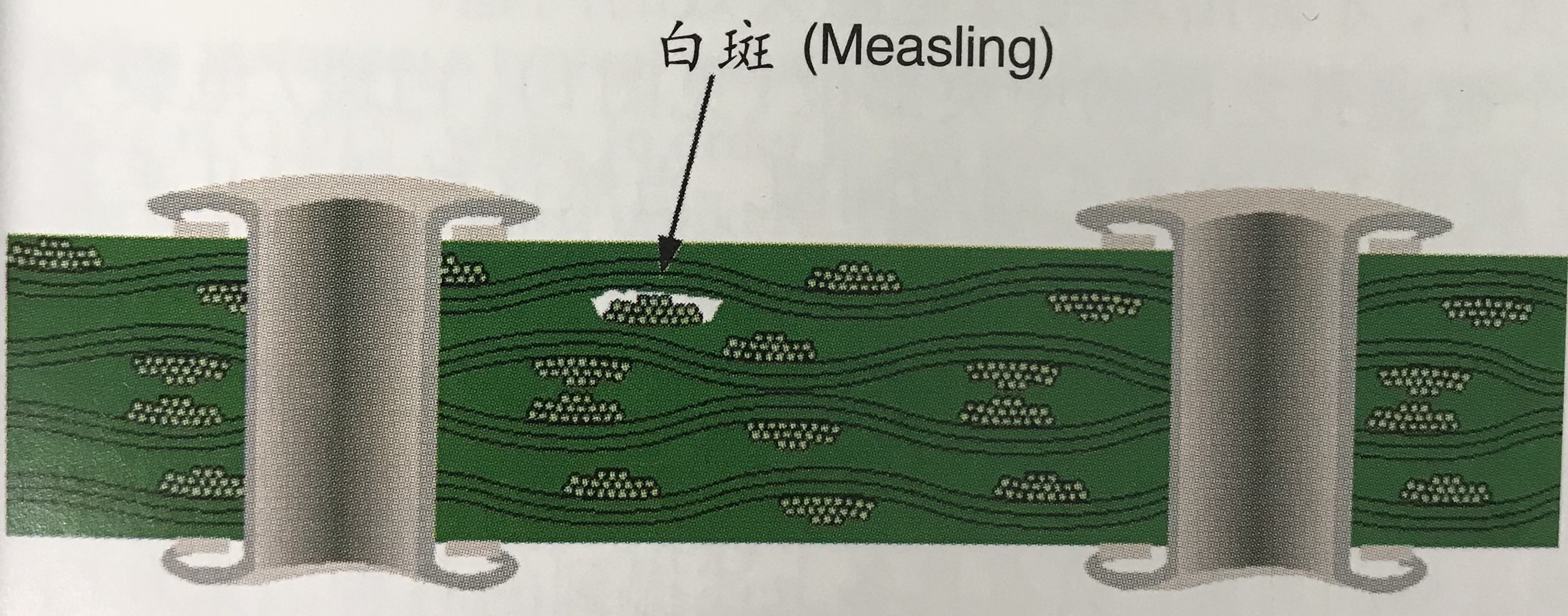

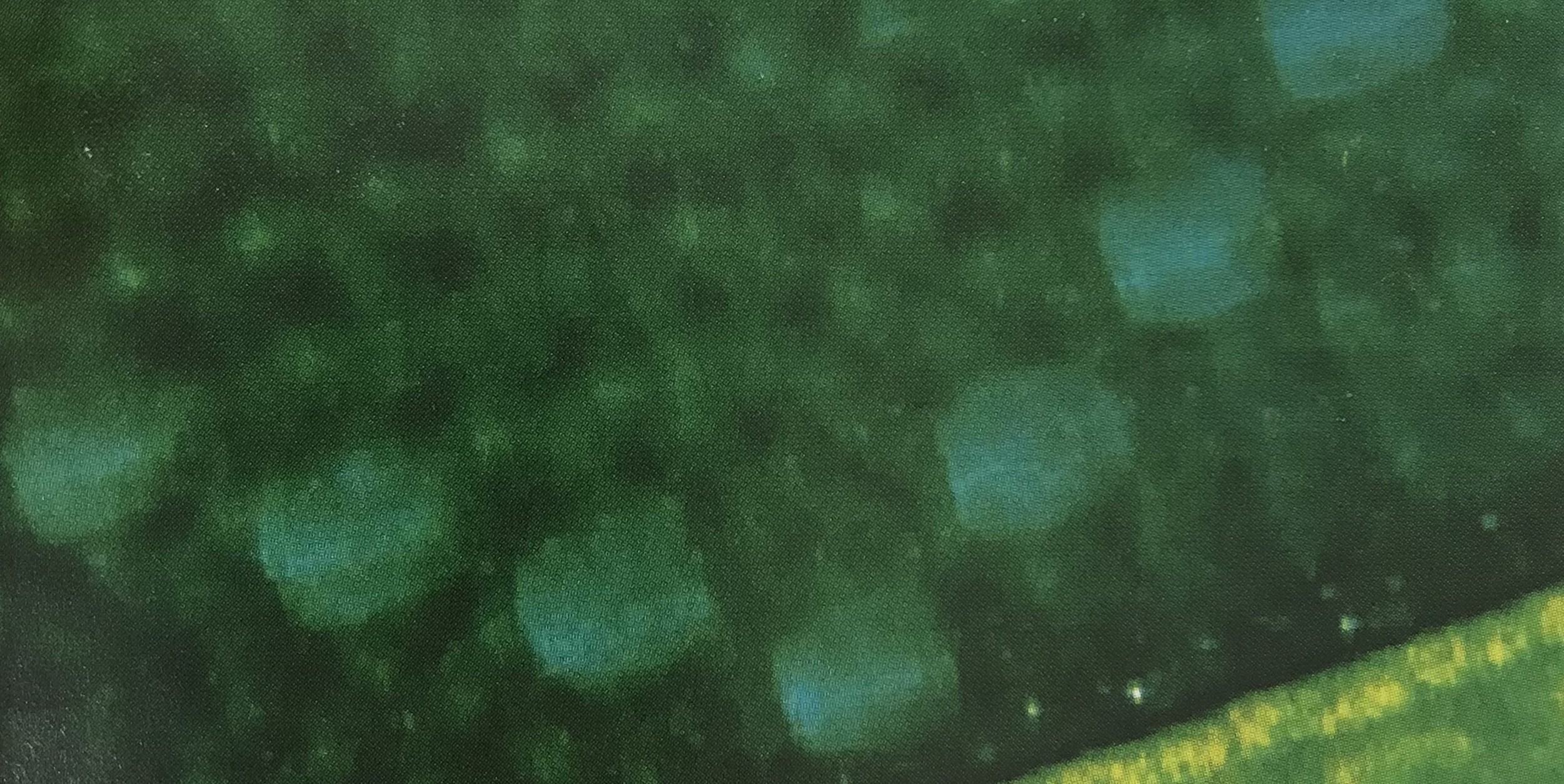

Measling of printed boards has been a self-inflicted industry-wide plague for many years. Measles is s sub-surface phenomena that have been found in new laminated materials and in every board type made from woven fiber reinforced laminates at one time or another. Since measles is strictly sub-surface phenomena and occur as a separation of fiber bundles intersections, their apparent positions relative to surface conductors have no significance.

Over a period of time, governing specifications have become excessively heavy regarding the Presence of measles. In addition, cosmetic appearance has become a major acceptance criterion. In actual fact, no failure has ever been attributed to measling, based on all military and industry testing to date. IPC, industry and various military agencies have conducted extensive testing in severely measled assemblies under extreme environmental conditions for long periods of time with no evidence of growth, spreading or any detriment to the function of the assembly. Measles should not be the cause of rejection.

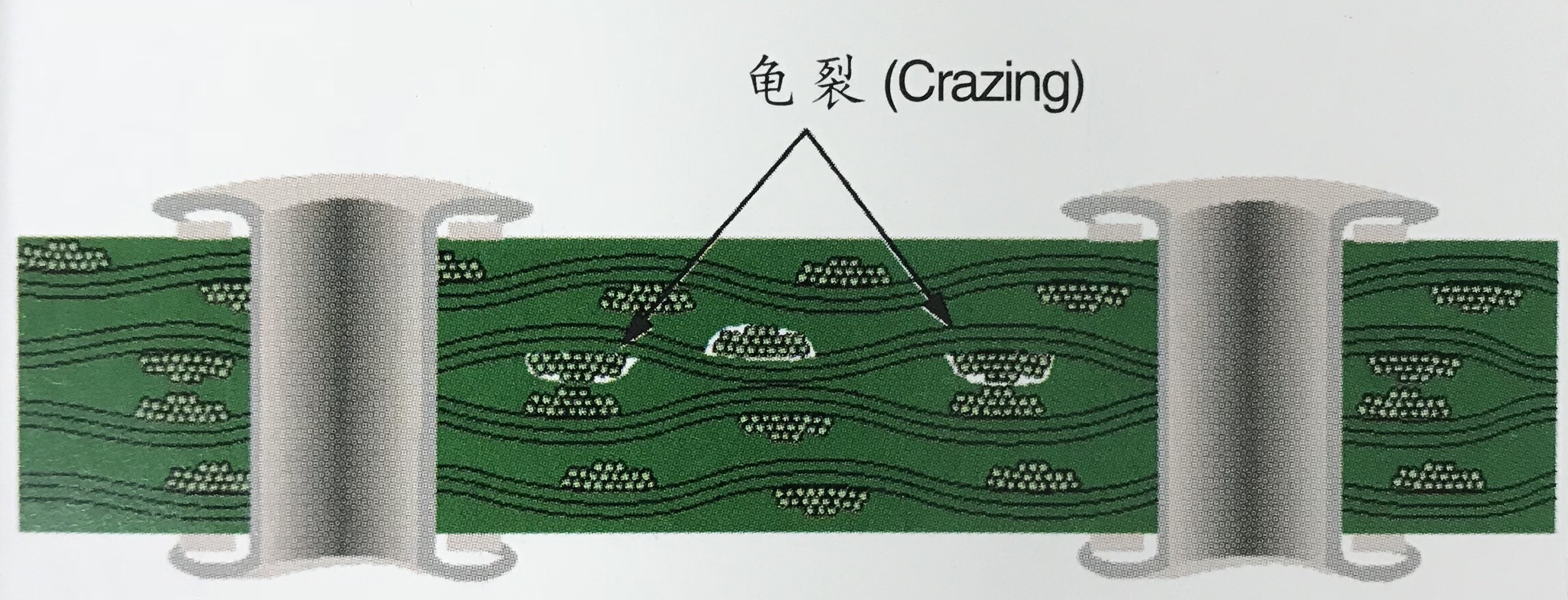

Measling is an internal condition occuring in the woven fiber reinforced laminated base material in which the bundles are separated at the weave intersection. The term “crazing” is something used to describe an array of measles which appear from appear from the delamination and should be addressed in accordance with the requirements nation.

Measles manifests itself in the form of discrete white squares or “crosses” below the surface of the base material, and is usually related to thermally induced stress.

Crazing is an internal condition occurring in the laminated base material in which the glass fibers are separated from the resin at the weave intersections. This condition manifests itself in the form of connected white spots or “crosses” below the surface of the base material, and is usually related to mechanically induced stress.

Maybe it’s helpful to you: