How does the China PCB industry adapt to the rapidly growing electronic age?

In recent decades, China's Printed Circuit Board (PCB) manufacturing industry has developed rapidly, ranking the world's first in terms of output value and total output. As electronic products change with each passing day and price wars change the structure of supply chain, China has become the world's most important printed circuit board production base with industrial distribution, cost and market advantages.

The printed circuit board has developed from Single Sided PCB to Double Sided PCB, Multilayer PCB and Flexible PCB, and has been developing towards high precision, high density and high reliability. In order to reduce the size, reduce the cost and improve the performance, the PCB will remain strong vitality in the future development of electronic products. The future development trend of PCB manufacturing technology is to develop in the direction of high density, high precision, fine aperture, thin wire, small spacing, high reliability, multi-layer, high-speed transmission, light weight and thin type.

PCB production capacity in Europe, the United States and Taiwan is continuously transferred to the mainland for the following three reasons:

1. Western countries have tightened their environmental policies and forced the transfer of PCB industries with relatively high emissions. Printed circuit boards contain heavy metal pollutants, which inevitably cause local environmental pollution during manufacturing. In Europe and the United States, the government of PCB manufacturers environmental requirements higher than domestic. Under the strict environmental protection standards, enterprises need to establish a more perfect environmental protection system, which will lead to the increase of environmental protection expenditure of enterprises, which will lead to the increase of administrative expenses and further affect the level of corporate profits. Therefore, European and American manufacturers only keep the high-technology and confidential PCB business such as military, aerospace, and small batch rapid board business, while continuously reducing the high-pollution, low-gross profit PCB business. Capacity in this part of the business has shifted to Asia, where environmental requirements are relatively lax and environmental spending relatively low. Strict environmental policies are also hampering the release of new capacity. PCB manufacturers typically expand capacity by expanding existing or new plants. But on the one hand, the restriction of environmental protection clause increases the difficulty of plant site selection.

On the other hand, the higher cost reduces the expected rate of return of the project, weakens the feasibility of the project, and increases the difficulty of raising funds. The pace of investment in new projects by European and American manufacturers is lower than that of Asian manufacturers due to the above two reasons, thus releasing relatively less new production capacity and continuing to lag behind the Asian region in PCB production capacity.

2. In the mainland market, western manufacturers tend to be at a disadvantage in price wars as they gain price advantage through relatively low labor costs. The labor cost in the mainland market has a relatively low advantage. Although it has been gradually improved in recent years, it is still far lower than that in developed countries in Europe and America, and also lower than that in Japan and South Korea. By virtue of their advantages in environmental expenditure and labor cost, mainland manufacturers can gain competitive advantage at a lower price than those in other regions and thereby expand their market share.

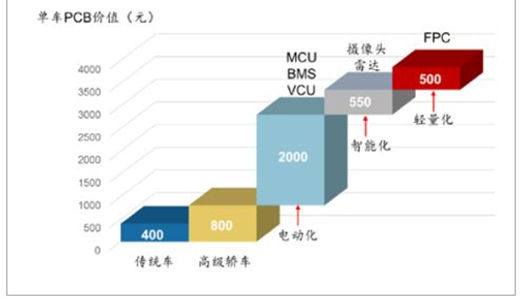

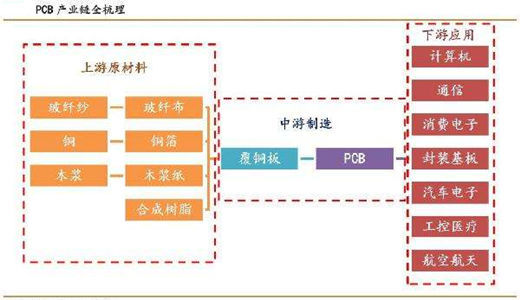

3. China has become the world's largest consumer electronics market, with a complete supporting PCB industry demand in the upstream and downstream industrial chain. In recent ten years, China's electronic information industry has been developing rapidly and its scale has been expanding constantly. In 2015, the annual revenue of China's consumer electronic information manufacturing industry reached 11.1 trillion yuan, the highest in the world. As one of the closest carriers to terminal products, PCB demand in the mainland will continue to grow with the popularity of downstream terminal products. In contrast, the supply side of the mainland has formed a complete industrial chain of "from copper foil, glass fiber, resin, copper clad sheet and finally made into PCB", which can support the growing production demand. Therefore, driven by demand, the industry capacity smoothly to the mainland

The boom in any electronic product has led to an industrial upgrade in the PCB industry.

Early digital products (MP3,MP4) triggered the PCB industry's rapid sample service, 24 hours of acceleration, 48 hours, 72 hours and so on; Whoever can seize the market in the first place will be competitive.

Smartphone early achievements of a batch of ODM mobile phone, mobile phone chain, led PCB, smartphones after rise, China's huawei, millet, OPPO companies such as the meteoric rise of more than half the world market share, which stimulates the development of the electronic industry chain, China's huge population dividend, sound industrial system, cheap labor, let China become the world's biggest consumer electronics market and manufacturing base for the development of semiconductor best time, is the best development opportunity, PCB PCB mobile phone manufacturers to move through the research and development technology, Upgrade equipment to meet the increasing demand for PCB manufacturing.

Energy-saving and environmental protection LED to the LED lighting market. In 2009, China suddenly added a large number of LED lighting manufacturers, leading the PCB industry to enter the high thermal conductivity, the aluminum substrate market demand increased, and LED soft LED light bar sales. Shenzhen hangfeng technology co., ltd. has also expanded its LED aluminum PCB business with the trend, providing many valuable Suggestions and support for customers of European and American transition lamps.

When e-cigarettes emerged, they became a mainstay of PCB manufacturers. Balance car also drove PCB industry chain. Smart home era, intelligent control board has also become the mainstream of PCB industry.

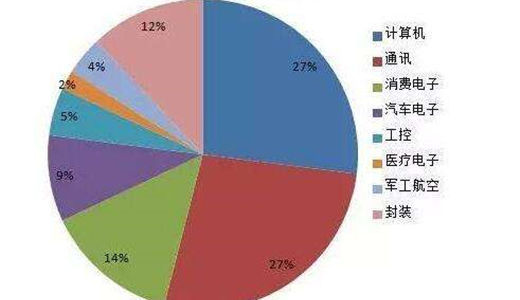

In an overview of the electronic age, PCB, an indispensable part of electronic products, has made a number of PCB enterprises and eliminated some. PCB is the most active industry in the modern electronic component industry as an essential basic part of electrical products. Due to the variation of product variety structure of the whole machine, although the required area of PCB in a single final product is gradually reduced, the value proportion of PCB in the cost of the whole machine is increased due to the improvement of product accuracy and complexity. In statistical data, PCB board is usually divided into single and double panel, multi-layer board, rigid flexible board, flexible board, HDI board and encapsulated substrate.

PCBQuick has made steady progress and stepped out of its own features over the past decade.

1. Customize PCB To Your Budget

2. PCB Solution for LED Strip, LED Lighting,...

3. 24Hours online quote for PCB Sample

4. Quick Turn PCB Prototype Service

5. One-Stop Service for LED Lighting Industry

6. PCB Copy & PCB Design Service