Why do we always insist on "100% full test" for PCB production?

Why do we always insist on "100% full test" for PCB production?

No matter PCB proofing or small batch production, we always insist on "100% full test", even though many manufacturers still use the method of sampling test. As the name implies, full test refers to the test of each board, to ensure that the whole batch of 100% standard, the purpose of this is to ensure that the board of high quality, risk-free use. Sampling test is sampling test. If the sampling is ok, the whole batch of products will reach 100% standard by default. What are the risks of sampling? The most fatal is the product yield is not guaranteed, there will be short circuit, open circuit and other bad board, more serious is the use of defective board machine equipment directly scrapped.

A manufacturer publicly sampling the rate of compliance is 98-100%, just think, 98% compliance rate, 2% of the bad board will have what kind of loss? 20 out of every 1,000 PCS are unqualified. If the customer who orders is an automobile or heavy industry equipment, just imagine how serious the consequences will be brought by these 2% defective boards. These defective boards will lead to product performance and yield decline, can not be put into use.

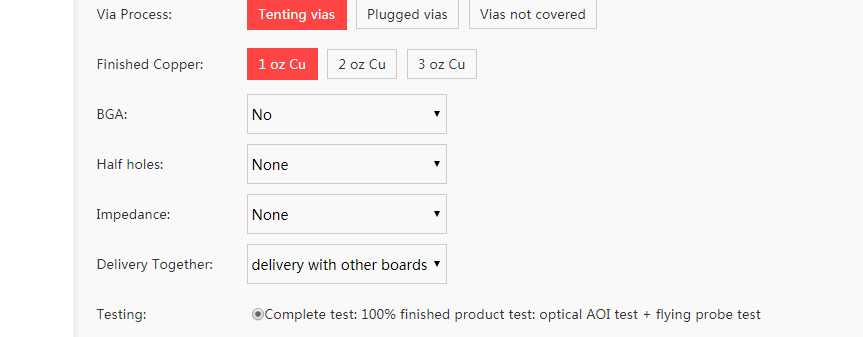

PCBQuick does not have the option of "random test", PCBQuick defaults to "100% full test", to ensure the high quality of each board, quality is the survival of the enterprise.