How to Detect Printed Circuit Board Failure?

There are many precautions for the fault detection of the printed circuit board, and we need to follow the correct methods and steps to operate.

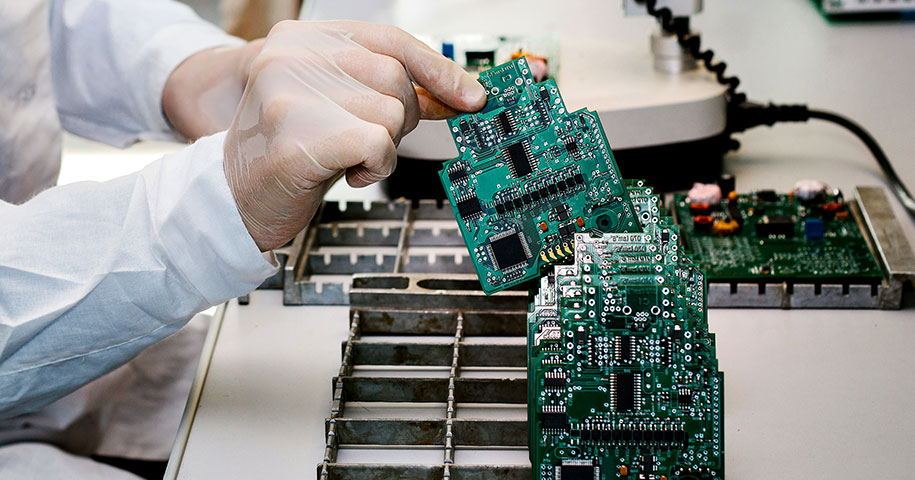

Visual inspection

Appearance: Whether the device package is broken or deformed, the electrolytic capacitor is swollen, and the lead wire is warped.

Distinguish color: whether there is any component packaging, lead blackening, discoloration, etc.

Smell: Are there any components that emit a burnt smell.

The printed circuit board assembly with the above phenomena can be directly judged as faulty components and replaced, so as not to interfere with the subsequent tests.

Power short-circuit check

Identify short circuits

The power supply usually has a resistance of more than tens of ohms to the ground. Use a maintenance tester to check the resistance between the power supply and the ground on the PCB board under test. The resistance is usually 70-80 ohms or more. In other words, if there are components on the circuit board that is short-circuited or partially broken down, measures must be taken to find out the components that have been broken down.

1. Find or confirm the power and ground terminals on the circuit board

2. Confirm through the power socket on the circuit board or the silkscreen near the relevant pins

3. Start with the electrolytic capacitor on the board

If there is a large electrolytic capacitor on the printed circuit board, it is generally used for filtering. The positive and negative pins of the electrolytic capacitor will be hung between the power supply and the ground on the circuit board. At this time, the polarity of the capacitor is also distinguished. It is equivalent to finding the power and ground terminals of the circuit board, refer to the following figure:

4. Start with the relevant IC on the printed circuit board

As long as the IC on the printed circuit board has a certain model, we can confirm the power pin and ground pin by looking up the package structure drawing of the IC.

Find short circuit point

In printed circuit board maintenance, if you encounter a short-circuit of the public power supply, the fault is often big, because many devices on the board often share the same power supply, and every device using this power supply is suspected of short-circuiting. If there are not many components on the board, use " The method of "hoeing the earth" can eventually find the short-circuit point. If there are too many components, whether the "hoeing the earth" can hoe the situation depends on luck. Here are some more effective methods recommended. After adopting these methods, you can get twice the result with half the effort, and you can often find the point of failure quickly.

1. One of the methods to find the short-circuit point of the power supply:

Turn on the DC stabilized power supply, adjust the open-circuit voltage to the device power supply voltage level, first adjust the current to the minimum, and add this voltage to the power supply voltage point of the circuit, such as the VCC (5V) and GND (0V) terminals of the 74 series chip. Regardless of the degree of short-circuit, slowly increase the current and touch the device with your hand. When you touch a device that heats up significantly, this is often a short-circuited component, which can be removed for further measurement and confirmation. Of course, the voltage must not exceed the working voltage of the device during operation, and the connection cannot be reversed, otherwise, it will burn out other good devices.

2. The second method of finding the short-circuit point of the power supply:

Use a professional short-circuit tracker for detection.

Screen overheated components

After confirming that the power supply is not short-circuited, consider using a regulated power supply to power up the circuit board for the purpose of troubleshooting overheated components. Be very careful in this step. Must guarantee:

1. If there is a filter capacitor with a higher withstand voltage and a larger capacity on the tested board, discharge the filter capacitor first.

2. It must not be reversed. This can lead to disastrous consequences.

3. The voltage cannot exceed the working voltage of the board. What is the working voltage? In addition to measuring directly to the device, it requires certain experience to determine the working voltage of the printed circuit board. A more commonly used method is to infer from the operating voltage of the device connected to the power supply. For example, if a 74 series device is hung on the power supply, the voltage is generally 5V.

After power on, quickly touch the temperature of the components on the board with your hands. If the temperature of any component is too high (it requires some experience to judge it), it can be judged as a faulty component. Replace it after power off. Repeat this process until there are no overheated components on the board after stable power-on.

Check if there is memory supported by battery (or large capacitor) on the board under test

Some printing circuit boards, mainly CPU boards, may have memory supported by batteries (large capacitors). Once the content of the memory is lost, even if the printing circuit board is good, it may cause the entire device to fail to boot. Therefore, if you are not sure that you can rewrite the content, you must be extra careful when testing this circuit board. pay attention:

1. Do not use tools such as maintenance tester or multimeter to test the power supply and chip selection pins of this kind of memory, otherwise, the content will be lost;

2. When using the memory test function of the tester, unless the contents have been correctly read out and saved, the test function with the "write" operation cannot be used.

We are a professional PCB production manufacture. We can provide customers with one-stop services from PCB production, component procurement, to component assembly. If you want to buy a high-quality printed circuit board, please contact us immediately!

Previous

How to Assemble PCB?