The Precautions in PCB Boards Manufacturing and Transportation

In order to prevent premature damage to the circuit board, we need to understand various PCB handling precautions and use them in the following circuit board development, testing, and transportation processes.

Development

Avoid exposing copper traces to air

If the copper traces of the circuit board are exposed to the air, especially when there is a long time interval between manufacturing and assembly, they may be oxidized and contaminated. The best way to avoid this situation is to make the surface as smooth as possible during the manufacturing process.

Avoid debris

During PCB assembly (PCBA), debris may accumulate on the board. Since the debris is small, it may be difficult to find. Therefore, it is best to use optical inspection and clean the circuit board after assembly.

Avoid excessive stress

When manually handling the circuit board, it is necessary to avoid applying excessive pressure to the circuit board. Excessive pressure may cause the circuit board to deform or break, thereby affecting the integrity of the circuit board structure.

Wear protection

It is also possible to deposit contaminants when handling the board manually. This includes dust, sweat, etc. Therefore, you should wear gloves when handling.

When prototyping, it is necessary to avoid bad PCB handling methods, otherwise, it will delay the progress of development. For example, a contaminated circuit board will produce unstable behavior, which makes it difficult to perform accurate tests.

Testing

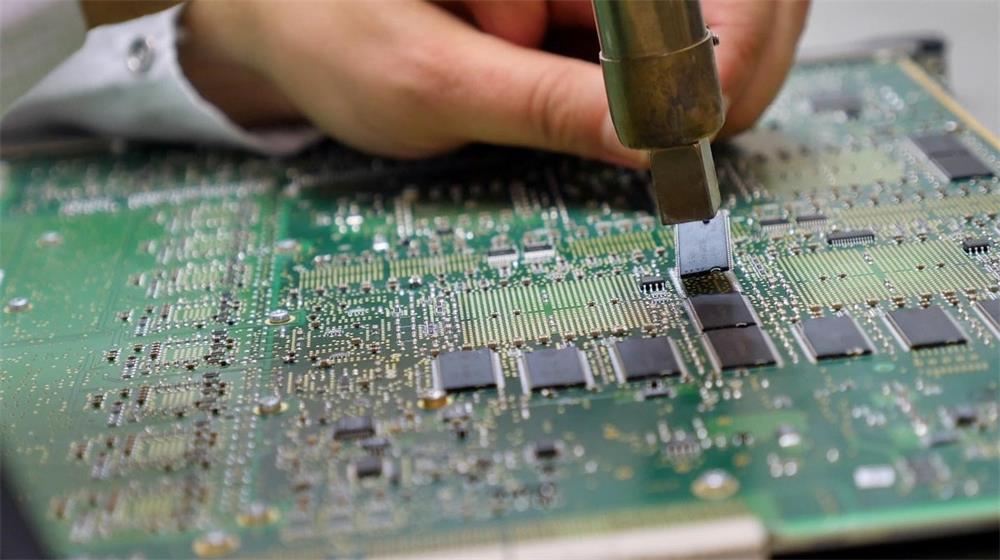

Use tools carefully

Be careful when working on the circuit board. For boards, this is very important. If you are not careful, it can cause a lot of damage, so it is very important to use the appropriate tools.

Pay attention to moisture

If the temperature difference between the surface of the circuit board and its surrounding environment is too large, the circuit board may become wet, which will affect the accuracy of the test. So you should pay attention to the test in a ventilated environment, and control the temperature of the test environment to avoid this situation.

Transportation

Maintain a controlled environment

It may be necessary to adjust the internal environment when transporting the PCB. In long-distance transportation or in bad weather, strict attention is required. It is recommended that the ambient temperature be lower than 30°C (86°F) and 85% RH.

Make sure the board is packaged correctly

The PCBA must be properly packaged. However, the requirements may vary due to the following factors: shipping time, ambient temperature, and whether the board has a conformal coating or is individually packaged.

Avoid moisture

It may be necessary to adjust the internal environment when transporting the PCB. In long-distance transportation or in bad weather, strict attention is required. It is recommended that the ambient temperature be lower than 30°C (86°F) and 85% RH.

Taking appropriate precautions during the circuit board production process will reduce the occurrence of many failures. If you want to know more about printed circuit boards after reading the above, you can get professional solutions by contacting us.

As a professional PCB product manufacturer, we have won praise and trust from many customers with our excellent R&D technology and high-quality products. We have a professional production team and strict quality inspection system, which can test and inspect all aspects of product quality. At the same time, we will provide thoughtful one-stop service and effective solution technology according to the actual needs of customers. If you are interested in our printed circuit boards, please contact us immediately!