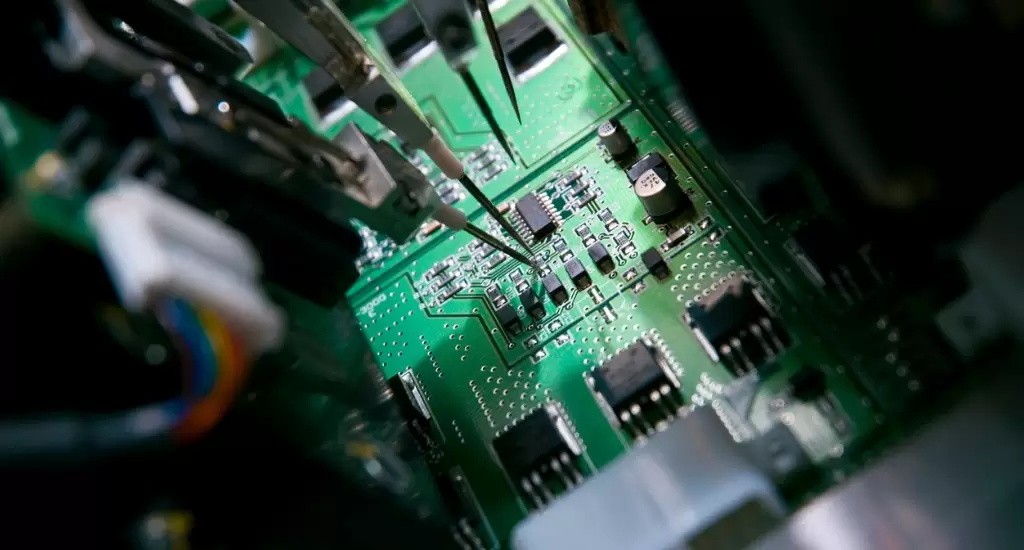

Common Causes and Solutions of Printed Circuit Board Failures

Printed circuit boards are an indispensable part of electronic components and play a central role. In a series of PCB production processes, if there is improper operation, PCB quality problems will emerge endlessly. The followings are common causes and solutions for printed circuit board failures.

1. The PCB board is often delamination in use

(1) Supplier material or process problem

(2) Poor design material selection and copper surface distribution

(3) The storage time is too long, the storage period is exceeded, and the PCB board is damp

Choose the packaging and use constant temperature and humidity equipment for storage. Do a good job of the PCB factory reliability test, for example: in the thermal stress test in the PCB reliability test, PCB QUICK regards more than 5 times of no delamination as the standard and will confirm it in the sample stage and every cycle of mass production. The general manufacturer may only request 2 times and only confirm once a few months.

2. The solderability of the PCB board is poor

The reason is that the PCB board is placed for too long, which causes moisture absorption, the layout is contaminated and oxidized, and the black nickel is abnormal

Strict attention should be paid to the manufacturer's quality control plan and standards for maintenance when purchasing. For example, for black nickel, it needs to see whether the concentration of the gold wire solution used by the PCB board manufacturer is stable, whether the analysis frequency is sufficient, whether there is a regular stripping test and phosphorus content test for testing, whether the internal solderability test is well-executed, etc.

3. The PCB board is bent and warped

The supplier's selection of materials is unreasonable, improper storage, abnormal operation lines, obvious differences in the copper area of each layer, and insufficient production of broken holes.

The countermeasure is to pressurize the thin board with a wood pulp board before packaging and shipping to avoid deformation in the future. If necessary, add a clamp to the patch to prevent the device from bending the board excessively. The PCB needs to simulate the mounting IR conditions for testing before packaging, so as to avoid the undesirable phenomenon of plate bending after the furnace.

4. PCB board impedance is poor

The impedance difference between PCB batches is relatively large.

Manufacturers are required to attach batch test reports and impedance strips when delivering them. If necessary, they are required to provide comparative data onboard inner wire diameter and board edge wire diameter.

5. Anti-welding blistering/falling off

There are differences in the selection of solder mask inks. The solder mask process of PCB board is abnormal, caused by heavy industry or excessively high patch temperature.

PCB suppliers should formulate reliability test requirements for PCB boards and control them in different production processes.

PCB QUICK is a high-tech enterprise specializing in the export and mass production of printed circuit board samples. We specialize in the production of single-sided PCB, double-sided PCB, multilayer PCB, aluminum PCB, and flexible PCB. If you have a need for this, please search for related products on our website and contact us directly.

As a professional PCB product manufacturer, our products are widely used in high-tech fields such as communications, computer technology, industrial control, automobiles, and LED lighting. We are committed to meeting the needs of customers in different industries in terms of quality, delivery, and cost-effectiveness, and PCB solutions, and also provide special customized services. Our professional service attitude has also won the praise and trust of many customers. If you want to buy our PCB products, please contact us immediately!